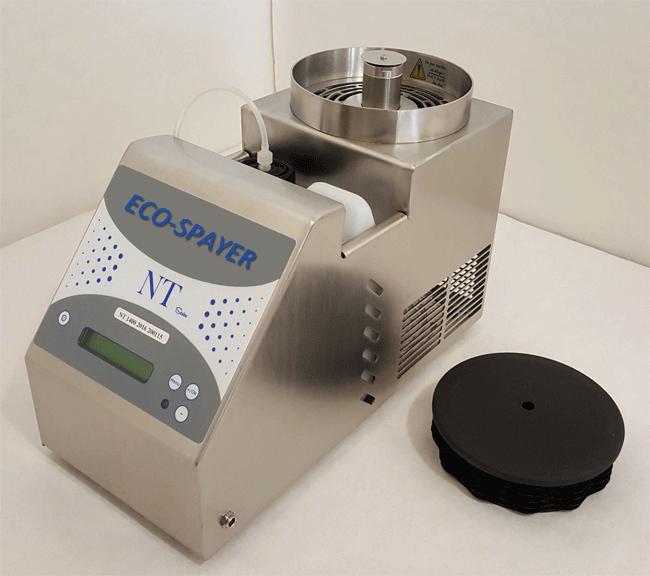

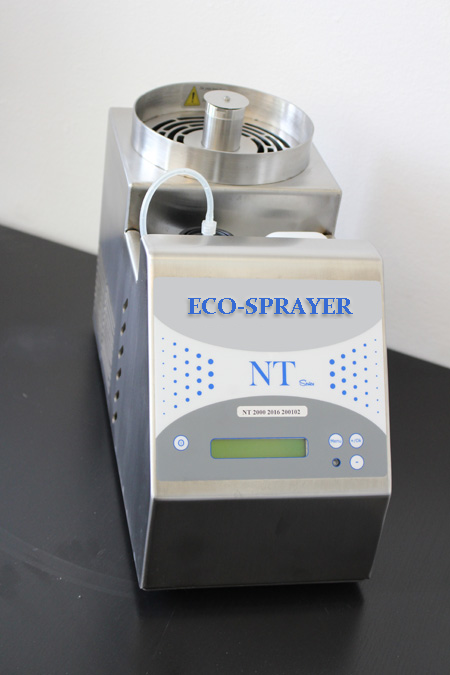

Pulverizer / Nebulizer, Airborne disinfection

Rotating disk technology (control of diffusion of micro-particle disinfection products, spraying on surfaces)

We offer several types of surfaces disinfection systems. Machines capable of disinfecting small areas of 5m3 up to 6000 m3.

.

Via fine disinfectant particles, fine droplets will be deposited on surfaces, eliminating all types of viruses and bacteria.

Disinfection of hospitals, clean rooms, laminar hoods, hangars, food, bacteria, fungi, our machines can be used with many viscous or non-viscous disinfectant products. Most of the time H2O2 peroxide is used.

We can adapt our machines according to your needs:

- We adapt the debit power

- We adapt to different disinfection products

-We adapt to your volumes (smalls or larges)

Endowed with the technology of the rotating (spinning) disc this innovative device allows, a perfect control(master's degree) of difusion, for the disinfection by air traffic of surfaces. Risk control infectious, decontamination of one places until 384 m3 (hospitals, laboratories, pharmaceutical, food-processing, cosmetic industry, biotechnologies, the animal breeding and the logistics, ambulances, pet shops, veterinarians, bacteriology, schools .. ) Silent and very light device of table of 6 kg.

Of a debit(flow) of 800, 1400 or 2000 ml / hour, this atomizer of table in nébulisation vertical line works on sector. Its distribution (dissemination) is made by means of a ventilator the breath of which pulls(entails) the droplets of spray towards the edge of the disk. Fed by a pump péristaltique who(which) inhales(sucks up) the liquid to be spread(broadcasted) from a can of 1 liter connected(bound) with the atomizer by a supple(flexible) pipe in silicone.

The programming of the atomizerTakes place by settling(adjusting) push-buttons aligned near the integrated(joined) display. Thanks to these regulations, the atomizer can work continuously or by alternating cycles of distribution and break. If the broadcasting is continuously programmed, all the liquid is sprayed at one time. With breaks, the distribution of the liquid can last longer. To calculate the duration of spraying(pulverizing) by air traffic, it is necessary to divide the volume of liquid by the debit of the machine. So, a volume of 200 ml of liquid will be sprayed(pulverized) in 30 minutes with a device the flow of which is of 400 ml / hour.

To schedule(program) the utensil, It is enough to settle(adjust) correctly the various to fonctions.

To fix the cycles of spraying(pulverizing), there is a function C (cycles), which could be scheduled(programmed) from 1 to 99. The continuous distribution (broadcasting) obtains by settling(adjusting) C on her(it) valeur1.

The duration of spraying obtains by settling the function D (duration), programmable from 0 at 99 minutes and 59 seconds. Every cycle of actual spraying is scheduled by settling D by not of 1 second. For the volume of 200 ml of liquid of the previous example, 10 cycles of 3 minutes each are going to spread the whole lot with the flow of 400ml/hour.

Data sheets

| Motor | BRUSHLESS |

| Ventilator | 180 m3/h - 24 V CC |

| Pump | Peristaltic |

| Mains supply | 100 à 250 V, 50-60 Hz |

| Speed rotation disk | > à 40000 RPM |

| Maximum electric power | 75 Watts |

| Check(Control) presence of liquid | presence |

| Fluid flow | 800 mL/h. |

| Weight | 6 Kg. |

| Reservoir | 500 mL. |

| Width | 160 mm. |

| Depth | 355 mm. |

| Feight | 240 mm. |

| Joints | PTFE |

| Automatic drain | Yes |

| Sound level | 54dB |

| Material | INOX 304L |

| Price : | Consult us |

Data sheets

| Motor | BRUSHLESS |

| Ventilator | 330 m3/h - 24 V CC |

| Pump | Peristaltic |

| Mains supply | 100 à 250 V, 50-60 Hz |

| Speed rotation disk | > à 40000 RPM |

| Maximum electric power | 75 Watts |

| Check(Control) presence of liquid | presence |

| Fluid flow | 1400 mL/h. |

| Weight | 6 Kg. |

| Reservoir | 500 mL. |

| Width | 160 mm. |

| Depth | 355 mm. |

| Feight | 240 mm. |

| Joints | PTFE |

| Automatic drain | Yes |

| Sound level | 54dB |

| Material | INOX 304L |

| Price : | Consult us |

Data sheets

| Motor | BRUSHLESS |

| Ventilator | 380 m3/h - 24 V CC |

| Pump | Peristaltic |

| Mains supply | 100 à 250 V, 50-60 Hz |

| Speed rotation disk | > à 40000 RPM |

| Maximum electric power | 75 Watts |

| Check(Control) presence of liquid | presence |

| Fluid flow | 2000 mL/h. |

| Weight | 6 Kg. |

| Reservoir | 500 mL. |

| Width | 160 mm. |

| Depth | 355 mm. |

| Feight | 240 mm. |

| Joints | PTFE |

| Automatic drain | Yes |

| Sound level | 54dB |

| Material | INOX 304L |

| Price : | Consult us |

Our devices are specially adapted to this type( of use. As which could act on small surfaces without trace nor of coulures, our machines are corresponding to the NF standards T72-281 . The NF Standards T72-281 is a conformity of a device coupled with a disinfecting product, allowing to eliminate a number of bacteria and from virus.

Our devices are specially adapted to this type( of use. As which could act on small surfaces without trace nor of coulures, our machines are corresponding to the NF standards T72-281 . The NF Standards T72-281 is a conformity of a device coupled with a disinfecting product, allowing to eliminate a number of bacteria and from virus.

Partagez sur les reseaux socio, nous faire connaitre sur vos pages.